![]()

![]()

![]()

![]()

![]()

![]()

![]()

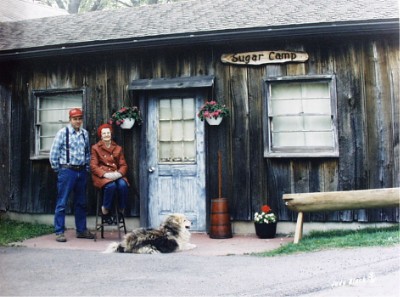

(Gary Blocher and his mother, Mildred)

![]()

![]()

![]()

![]()

![]()

![]()

![]()

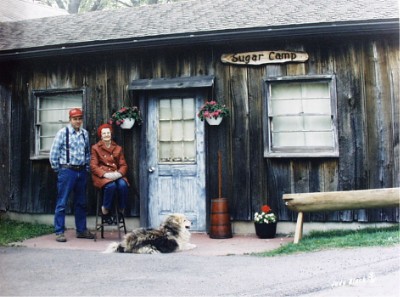

(Gary Blocher and his mother, Mildred)

According to legend, Indians first produced maple syrup when a brave stuck his tomahawk in a maple tree. The Story relates that the sap flowed into a container left at the base of the tree. The Indian squaw, believing the clear liquid to be water, placed the container over the fire. The boiling resulted in a sweet flavor and so maple syrup was produced.

Although there are many such stories told, we do know that early settlers produced and used maple syrup as a basic sweetener. In early times, gashes were cut in the maple trees to allow the sap to flow, but it was soon discovered that drilling a hole in the tree resulted in good sap flow and less damage to the tree. Sap was probably collected in wooden or clay trough like containers in very early processes, but wooden buckets or "keelers" soon replaced these. A wooden spout, or "spile", was placed in the hole in the tree to allow the sap to drip into the bucket.

Although equipment has been modernized, the basic process of producing maple syrup remains the same. Today, trees are tapped when they reach a diameter of 11 to 12 inches. A 7/16" diameter hole is drilled 2 1/2 to 3" deep in the tree each year. Sugar makers may use metal spouts and buckets to collect the sap or it may be gathered through a network of plastic tubing connecting the trees to a central collection tank.

The sap is available only during the dormant stage of the tree and will flow only when the temperature is above freezing. In early spring, nature causes the sap to flow within the tree as warmer temperatures remove the frost from the tree itself and the ground surrounding the tree. Thus it is practical to tap the trees in early spring with the approach of warmer weather. As the temperatures rise and the frost leaves the ground, the sap flows less freely and eventually stops and will not flow again until colder weather freezes the ground and sets the stage for another thaw. Thus varying weather conditions and rapid changes from sub-freezing temperatures causes sap flow and contributes to a good maple season. This is the basis for the common belief that cold nights and warm days are necessary for the production of maple syrup. In Pennsylvania, the average date for the opening of the season is the latter part of February, and the closing date is early April, although this changes with unusual weather conditions.

When sap has been collected, it is brought to the sugar house where there are usually several large storage tanks. Here the actual processing is done. It takes approximately fifty gallons of sap to produce one gallon of syrup. The wood or oil-fired evaporator, a large pan used for boiling the water from the sap, dominates the sugar house. The evaporator is usually a two-part arrangement. Today's modern evaporators have a series of flues in the bottom which trap heat and also give additional boiling area over the earlier flat-bottomed evaporator. Most evaporators are covered by hoods, which carry the steam from the boiling out through vents in the roof. Great white plumes of steam rising from the sugar house is a familiar sight in spring.

As the sap becomes more concentrated, it flows through a connecting pipe into the front pan of the evaporator- the syrup pan. This flat-bottomed pan is arranged with a series of baffles which directs the flow of the sap so that the sap is most concentrated in the section of the pan closest to the draw-off valve. This controlled flow pattern prevents the more dense sap from intermixing with the less concentrated and results in a better product.

Sap becomes syrup at approximately 7 degrees above the boiling point of water. Since the changes with elevation and barometric pressure, the temperature at which sap becomes syrup also changes. Most syrup producers check the density of their product using a hydrometer. Because of the volume of syrup and the amount of heat involved in the large evaporator, many producers draw syrup off the evaporator and transfer it to a finishing pan where it is easier to control the density. Finishing is usually done in a small flat-bottomed pan with a controllable heat source. The finished syrup is then filtered to remove an impurities, graded, and packaged either in drums for later use or in containers for immediate sale.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

The Making of Maple Products Page One

The Making of Maple Products Page Two

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()